TRACK

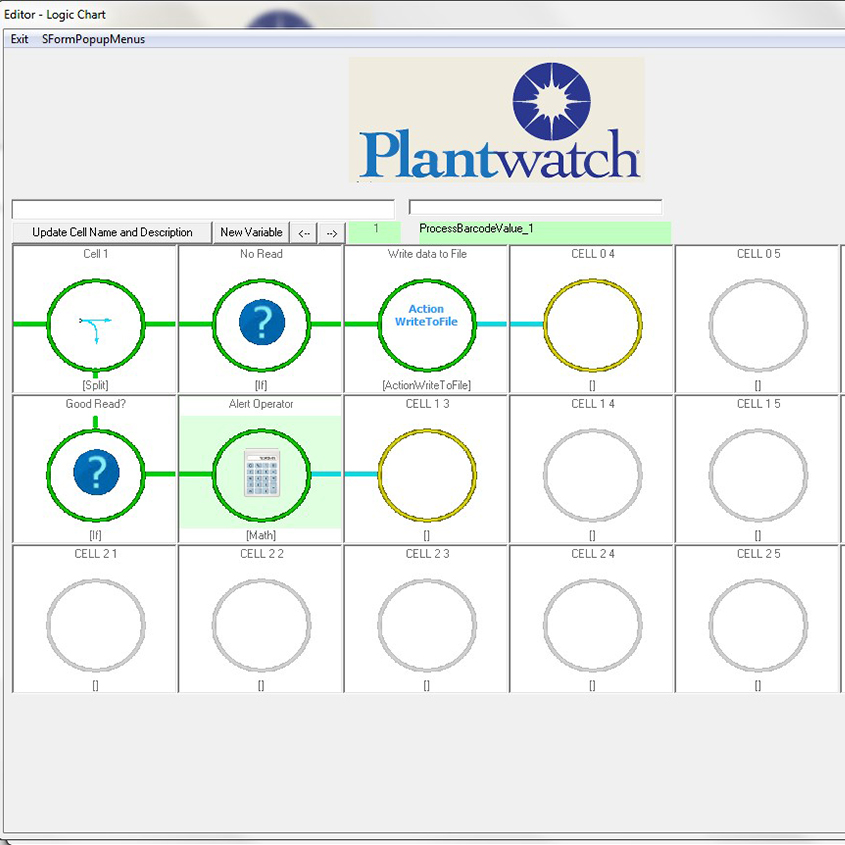

Plantwatch builds your supervisory control and data acquisition system with simple radio button configuration.

Plantwatch builds your supervisory control and data acquisition system with simple radio button configuration.

Product philosophy is to deliver an application builder software allowing our customers to develop and own their application with one day of training

Plantwatch builds in days your application specific to your process. Simple logic and fill in the blanks and you are controlling and data collecting from your lines or stations.

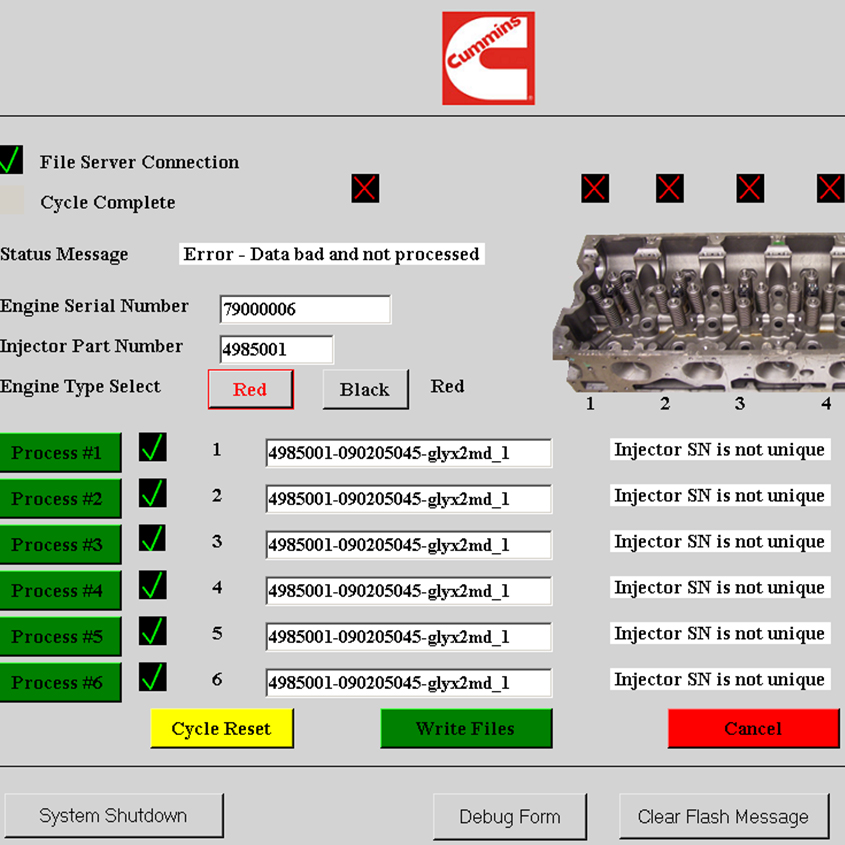

Manufacturing Execution Systems. Track, monitor, and control the production process and data flows on the factory floor.

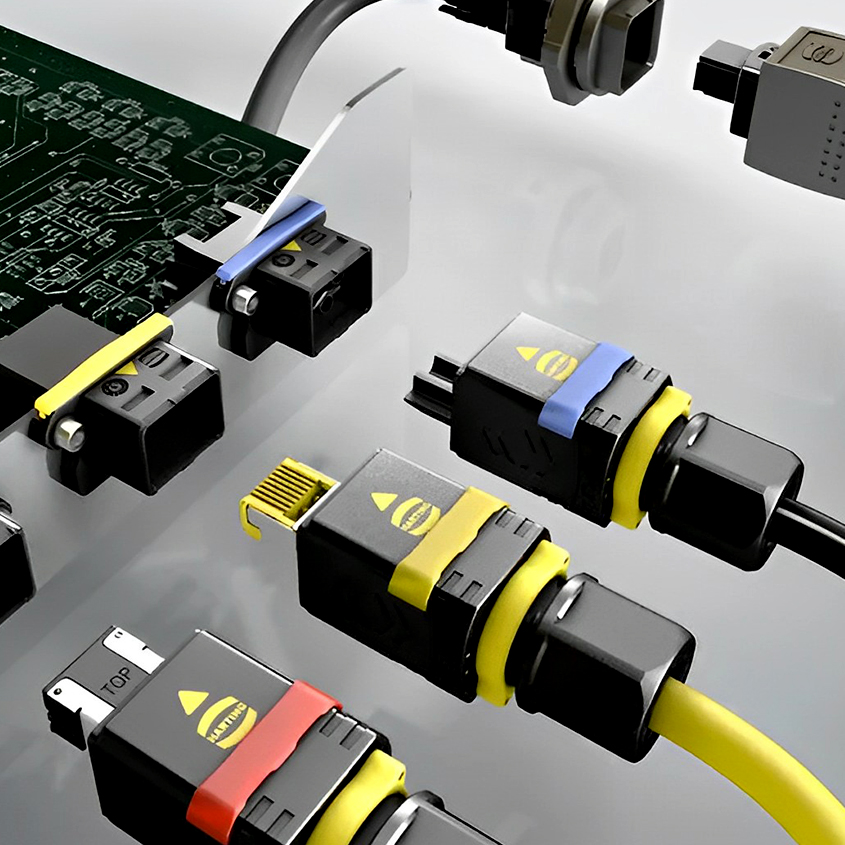

software and hardware components enable gathering of data from industrial equipment.

Error proofing with process control reduces build errors and ensures correct product routing.

Ensure high and consistent product quality with reduced defects

Traceability Software for Manufacturing

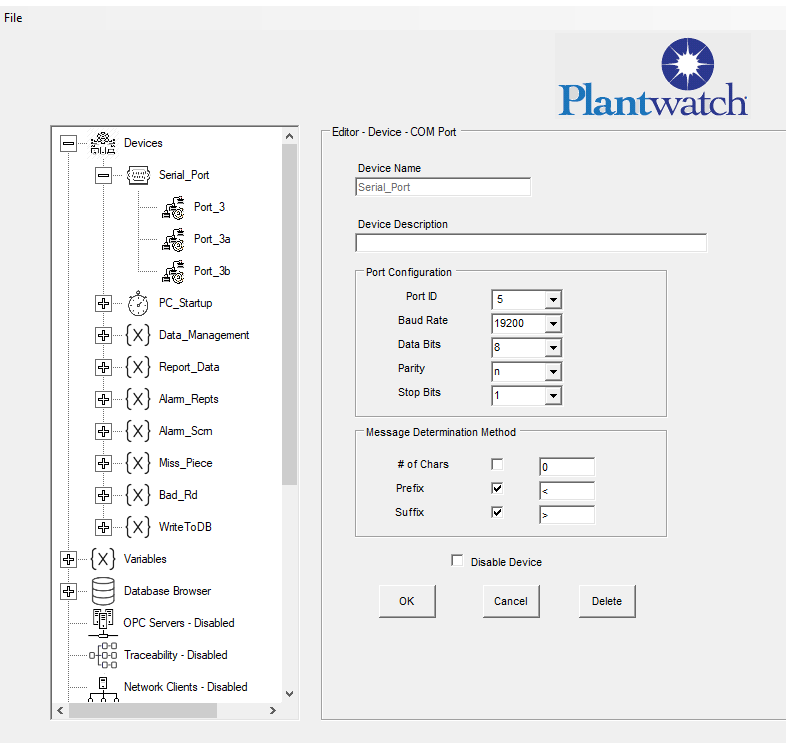

Configure your devices to communicate and create your tag variables.

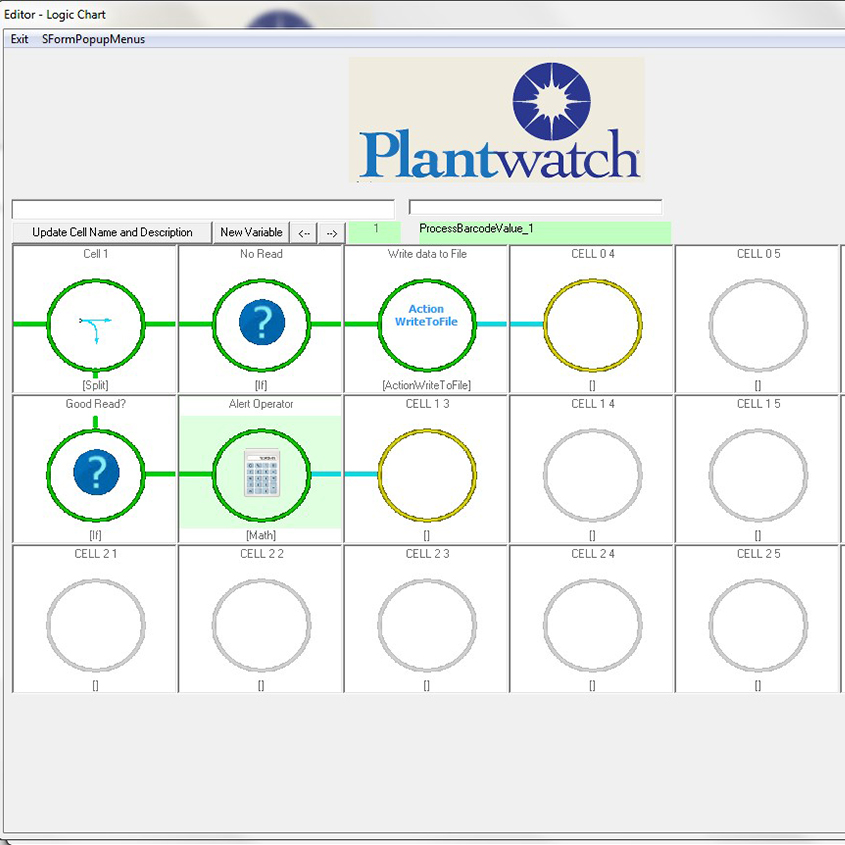

Build up your logic charts.

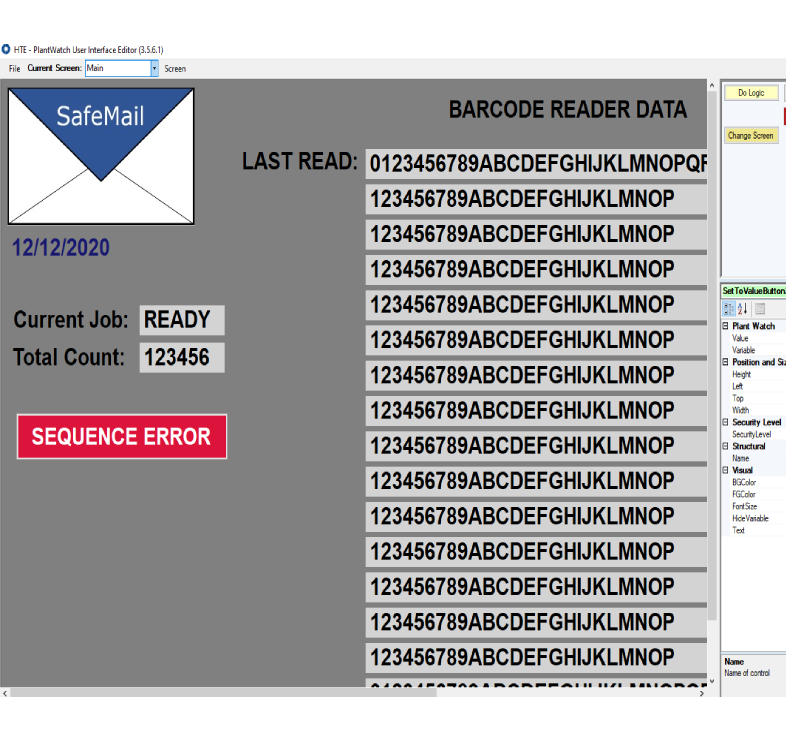

Build your graphic screens

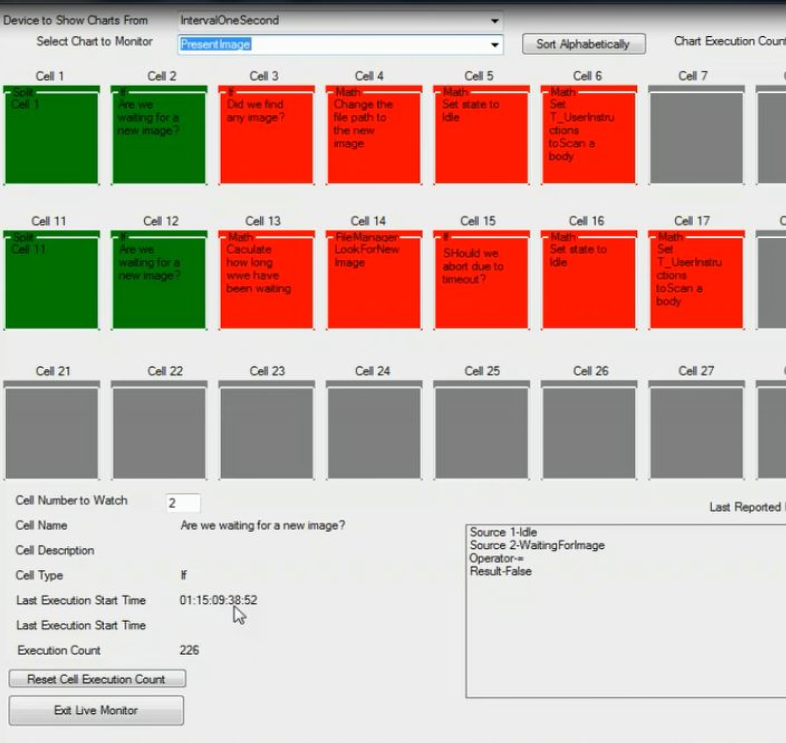

Run the application and watch your logic with live monitor

Serialized or Lot based operations can be monitored, controlled, and logged to provide you with valuable real time or historical information. Error proofing with process control reduces build errors and ensures correct product routing.

Product philosophy is to deliver an application builder software allowing for our customers to develop and own their application with one day of training

Plantwatch has a user-friendly graphics system where the user can create their desired screens with inputs, outputs, buttons, images, and more.

Plantwatch can communicate with a multitude of systems including: RS232, I/O, Ethernet, OPC & Structured Text File

Plant watch software and an Omron MicroHawk verifier assure the proper label is applied and proper amount of hooks are packaged.

PWatch_1comm

PWatch_2Variables

No products in the cart.