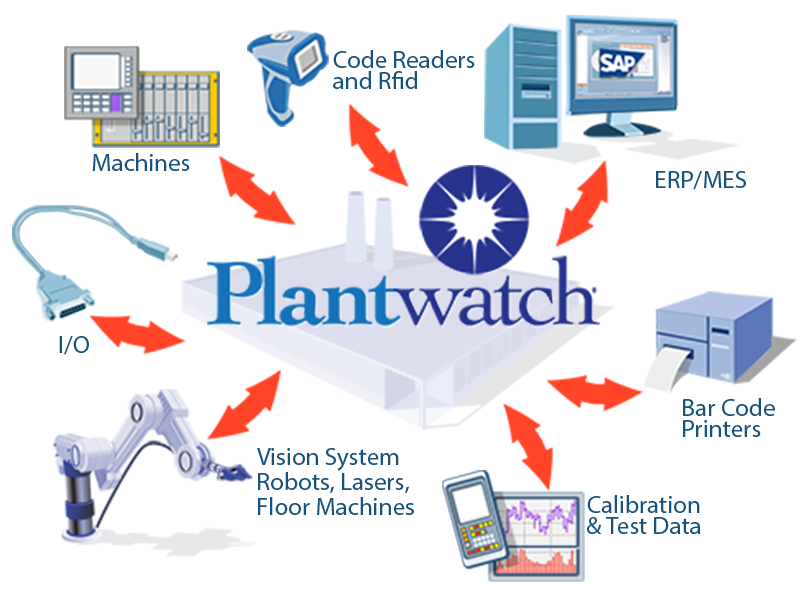

An easy-to-use Track, Control, and Visualization System.

Laser marking : Machine vision : Bar Code : Plantwatch

Our product for you

27 years in the business of Cameras, Bar codes and Lasers can guarantee your satisfaction. Plantwatch traceability software for manufacturing applications provide product traceability and data collection across a wide range of industries. Fill in the blank radio button configuration allows non programmers to build their custom solution. Powerful debug tools allow non-technical developers to build and extend their unique application. Serialized or Lot based operations can be monitored, controlled, and logged with one day of training.

Support 24/7

- Traceability

- Graphics

- Control

- Connectivity

- Database Browser

- File Manager

- Remote Executable

- Network Client

Our Story

1993 High Tech Enterprises starts with USDATA Factory link software, Nematron industrial computers, and ID Technology 1D bar code readers.

1996 Incorporated as HTEinc. and adds RVSI 2D scanneras and Machine vision including nerLite.

1999 listed contributor to AIAG B-17 Direct Part Marking standard.

2000 HTE creates Matrix Monitor verification software for GM and Ford powertrains.

2001 HTE starts Plantwatch Traceability software development.

2006 3-D Laser Vision product created for GM powertrain transmission snap ring inspection.

2014 Firepower marking Systems with Laser and Dot peen complete the Mark Read Track triad.

2016 FOBA high precision vision enabled laser markers. MRT application lab starts

2018 HTE signs contract with Omron automation.

2019 HTE announces MarkReadTrack division with the new website .

2020 HTE distributes Omron advanced sensing products and Sentech camera systems.

2020

Plantwatch version 4.1 released

2022

Feig RF-id integrated into plantwatch

2023

CCS vision lights partnership

Our Solutions

Plantwatch Software

Error Proofing, Serialized traceability, Pc based control systems, Line Automation , Data Collection , SCADA

Camera Systems

Omron Sentech Cameras, Laser line 3D Vision inspection, Machine vision inspection, Bar code reading systems, lighting and sensing.

Marking

Laser, Dot Peen , Ink , Labels. Laser workstations, in line marking systems, Light tight laser muzzle, vision based precision marking, day night , medical devices. Contract marking service

Custom Machines

Automation for cameras / lasers, Custom Graphical User Interfaces, Data collection and control systems, laser enclosures, material handling.

On-site Service

MRT supports other integrator's installations including: all the above systems regardless of manufacturer brand. Repair and maintenance of many camera and laser systems.

Product Manufacturers We Support