Why Choose Laser Cleaning? Unmatched Advantages

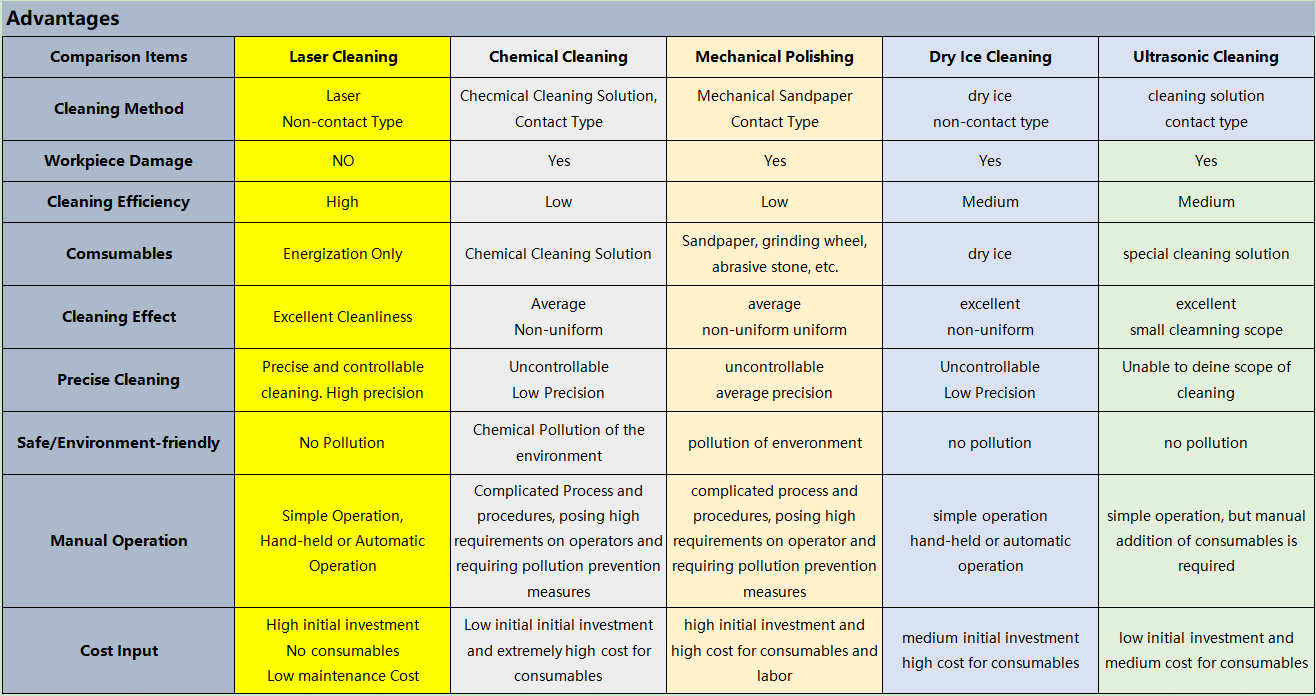

Ditch the costly, slow, and harmful traditional methods. Non-contact laser cleaning technology is the smart, superior alternative.

- Non-Destructive: Clean without abrasives or substrate damage.

- Eco-Friendly & Safe: Eliminate chemicals and toxic waste.

- Precision & Power: Achieve perfect results on any surface.

- Cost-Effective: Slash labor, disposal, and downtime costs.

Our Premier Solution: The Industrial-Grade Raycus Fiber Laser Source

At the core of our most powerful systems lies the Raycus Fiber Laser Source for industrial use. This isn’t just a component; it’s the engine of your cleaning operation. Renowned for its robustness and reliability, this source delivers the consistent high power needed for the toughest jobs. It’s the driving force behind our most effective industrial fiber laser cleaning system setups, designed for continuous operation in the most demanding environments.

Find the Perfect Laser Cleaning Machine for Your Needs

- For Mobility: The Handheld Fiber Laser Cleaner offers power and portability.

- For Heavy-Duty: The Industrial Fiber Laser Cleaning System automates large-scale cleaning.

- For Restoration: The Fiber Laser Machine for Paint Removal strips coatings without damage.

- For Rust: The Rust and Oxide Removal Laser restores metal to its original condition.

Experience the Mark Read Track Difference

Choosing the best fiber laser for surface cleaning means choosing a partner,Mark Read Track, committed to your success. We don’t just sell equipment; we offer complete solutions with overall support, training, and service.