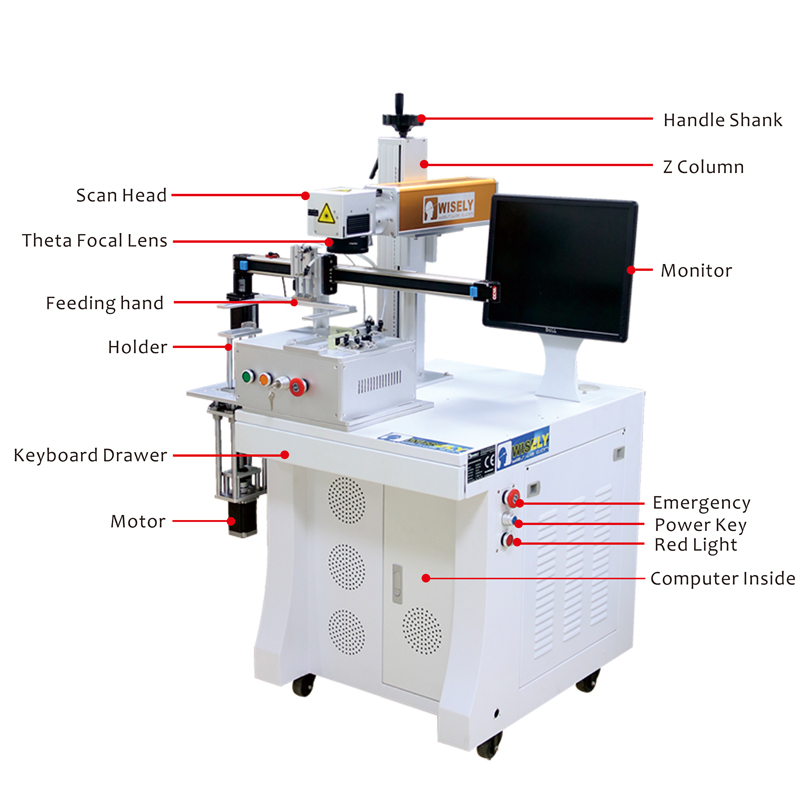

Overview of the Auto Feeding System

The Auto Feeding System is an advanced, PLC controller-based automation solution that works in perfect harmony with your fiber laser marking machine. It features a robust rail transmission system and a precise motor driving system to transport products to and from the marking area reliably. This turnkey system is engineered for 24/7 operation, delivering exceptional accuracy and repeatability for high-demand industrial applications, from electronics to automotive parts.