Machine Vision

Home » MRT Vision

It’s getting more powerful and affordable every day!

Image-based vision system solutions to help you meet all inspection and traceability requirements.

Home » MRT Vision

It’s getting more powerful and affordable every day!

Image-based vision system solutions to help you meet all inspection and traceability requirements.

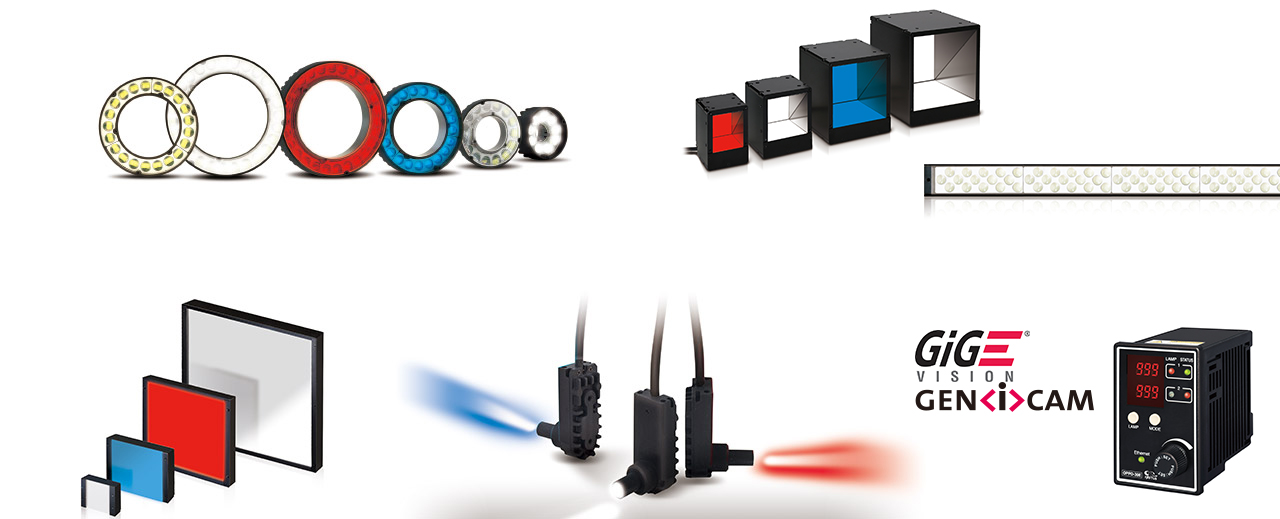

MRT provides Vision applications and all the required products at fair prices. Our comprehensive product line includes industrial cameras, smart and PC-based cameras, lighting, lens, and controls.

MRT designs and installs complete systems for many applications including

Error proofing assembly – Label inspection-Defect detection- Postal systems.

Smart Cameras- Line scan- Gig E- Lens- Lighting- Software

Great lakes factory automation vendor that can provide a fully integrated solution.

“If it can be done” but “should it be done”

The CameraLink Line Scan Model is the absolute top-notch precision solution for high-speed industrial images. Besides, it is a line camera specifically for industrial use that can handle difficult applications, and it has high-quality resolution and fast frame rates that enable it to reveal even the tiniest details on rotating or shifting surfaces. It is the cornerstone of robust Machine vision camera systems, providing the reliable data integrity required for critical quality control and traceability processes in modern manufacturing environments.

The CMOS Model from Mark Read Track redefines precision in industrial imaging. Engineered for demanding environments, this high-resolution machine vision camera integrates a powerful megapixel CMOS sensor to deliver exceptionally clear and accurate data. It is the cornerstone of any robust factory automation vision system, providing the reliability and detail necessary for flawless automated inspection and quality control processes.

Introducing the CoaXPress CMOS Line Scan Model, the complete future of precision inspection. Designed for unmatched speed and resolution, this camera establishes a new standard in industrial imaging. It is perfectly absorbed into time-pressed machine vision line scan systems, giving superior image clarity for the detection of even the tiniest defects. Enhance your production line with dependable, high-volume quality control and redefine the limits of automated inspection.

The FH Vision Systems are the height of AI-Powered Industrial Inspection, addressing the most complex quality control challenges. This powerful series combines state-of-the-art imaging and deep learning algorithms to provide the best accuracy and speed, thus giving production outcomes with no errors. It is at the heart of companies that are moving towards Smart Manufacturing Vision System capabilities, which assure no-defect output and the highest operational efficiency.

The FHV7 Smart Camera sets a new standard of accuracy in the manufacturing sector. Being a complete Industrial Machine Vision solution, it allows the combination of a robust processor, light source, and lens into one hardy unit. It has been designed for dependable use on the production floor so that it can provide you with the best speed and accuracy even during your most challenging Automated Visual Inspection processes, guaranteeing perfect quality of the products and boosting the production to its maximum.

The new CMOS Line Scan model will capture clean images of products and surfaces traveling across, making it excellent for speed applications. Made for the highest precision and efficiency for industrial-grade applications, this camera will become an essential part of any strong vision system created for precise quality control and automated optical inspection.

The OMRON SENTECH GigE Vision CMOS Model M Series has literally set a new standard for industrial imaging in terms of precision. This small-sized industrial camera, which has been designed in a way that it will not compromise on quality, is able to give very clear images and, at the same time, be very fast in processing, even for the most demanding applications. It is a truly industrial camera that can take the heat and, at the same time, give the accurate data you need to optimize your processes and maintain superior quality control, thus providing reliable performance in factory automation, robotics, and automated inspection systems.

Industrial Ethernet Smart Camera of MicroHAWK F430– The best in precision on any production line. MicroHAWK, the all-in-one compact vision system, is integrated with the finest global shutter sensor, high-performance processor, and intuitive software in a rigid camera housing certified IP65. Designed to render reliable services, it is used at an unbeatable speed and accuracy for the most demanding inspection, identification, and guiding tasks to warrant outstanding quality control and operational efficiency.

The MicroHAWK F440 Smart camera is an innovation in industrial vision. This compact vision system is the most powerful; integration of its hardware means a high-speed processor, tailored, embedded-centric LED, and I/O all in a single tool. As a solution, integration was a seamless process with innovative designs that delivered on quality. Reduced variation, so this quality claim would resist the monitoring of operation, as the production was mostly automated in its entirety.

Introducing the advanced USB 3.0 Model industrial camera, the precision imaging foundation that never compromises quality. This USB 3.0 camera can work under the most challenging conditions and still produce excellent images and very good performance. It is perfect for the pros who want to mix high-speed data transfer and full clarity for automatic checking and analyzing tasks perfectly, thus defining a new level of Industrial USB camera capabilities.

High-performance product with new functions.

Realizes unprecedented functionality through our unique technical development capacity.

By combining barcode reading and inspection tasks into a single device, the MicroHAWK platform offers manufacturers greater flexibility in production line layouts, cuts hardware-related costs and dramatically reduces wiring and maintenance work.

MRT helps manufacturers drive down costs, automate critical manufacturing processes and increase yields through data acquisition and control solutions. We offer versatile decoding power within the world’s smallest industrial barcode readers. With the highest-performance imaging engine in its class, MicroHAWK readers offer modular hardware options to take on any decoding task.