Laser marking : Machine vision : Bar Code : Plantwatch : Track-Pac

MRT consistentley achieves 99.9X read rates over time by implementing our proven Matrix Monitor verification software. Connected to scanning/verification cameras extensively throughout GM and Ford power train and their tier ones.

Features Include:

When an unreadable mark means scrapping the part, proper verification translates into higher production rates, lower scrap and a better bottom line. HTE’s solutions result in better running systems that will save money. Without a completely integrated solution of marking, verifying and reading, you’re just spending money. It’s time you start getting something in return.

- Camera independent

- Tied to control systems

- Graphical Interface

- Logged to SQL

- Error proofing

- Alarming

- Data Search tool

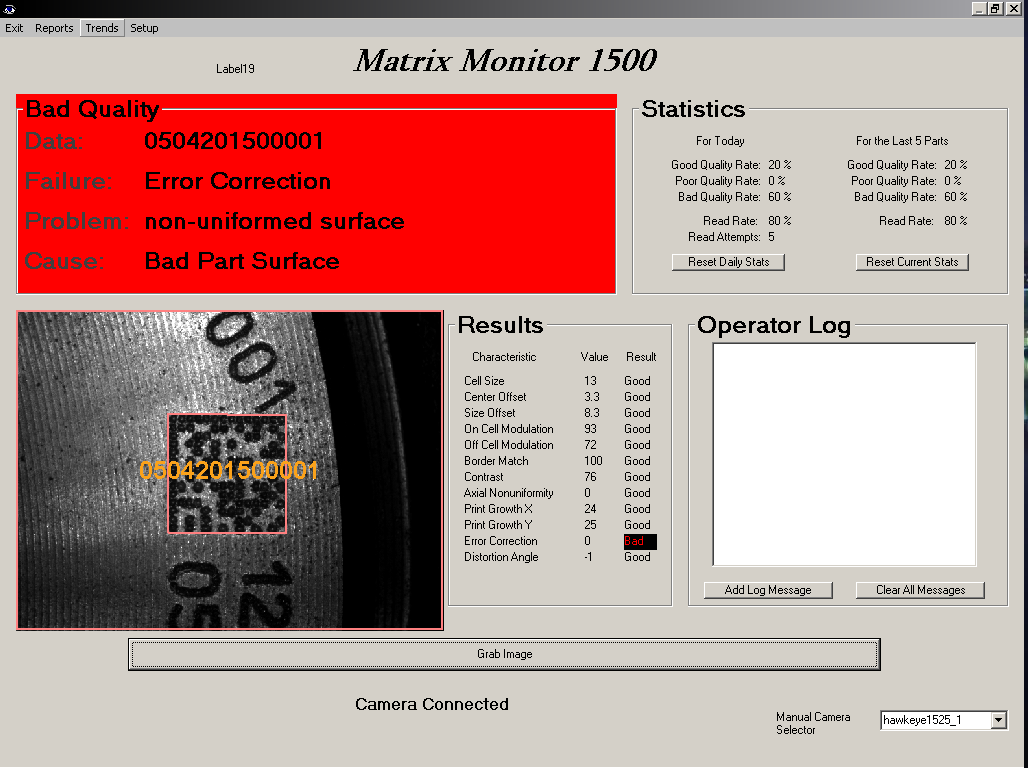

Print Quality Verification

Matrix Monitor provides evidence of compliance when downstream reading failures at your customer puts you in the hot seat.

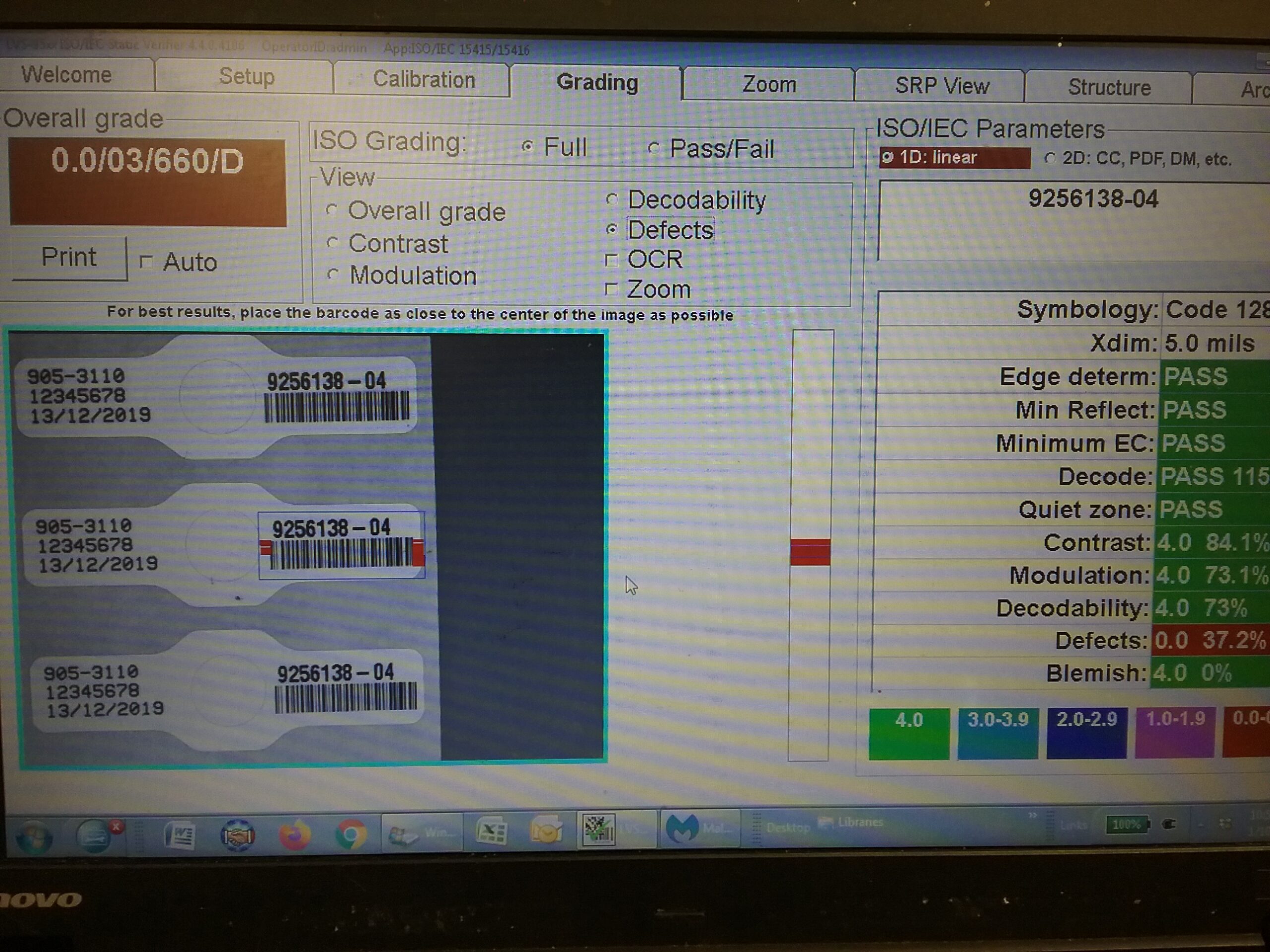

Bar Code Quality

Matrix Monitor DPM verifies bar codes while providing logging, reporting , statistics and editable messaging. Symbols that are directly marked by dot peen, laser etch and ink jet on materials such as metal, plastic, and rubber are gauged to determine compliance to OEM specifications. Matrix Monitor is a complete system used by OEM’s and suppliers to comply to strict requirements for 100% bar code quality verification.

Features Include:

- User Definable Limits

- Data Logging

- Operator Log

- Daily and hourly Statistics

- Historical Trending

- Alarming, Real-Time/Historical

- Data Search tool

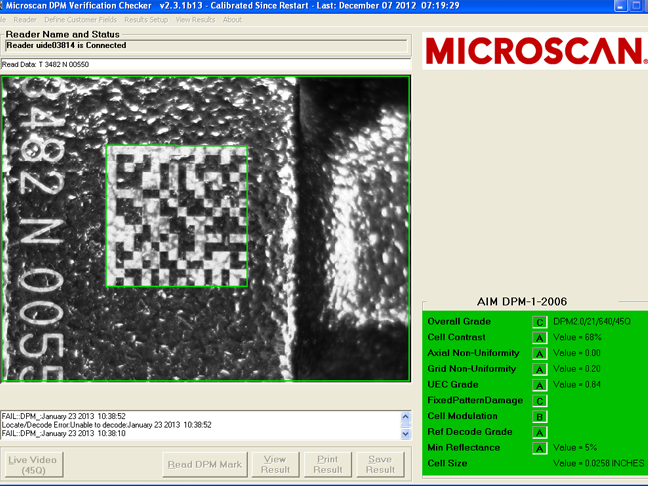

Direct Part Mark Verification example

HTE Inc. provides solutions and components for Automatic ID. Fixed mount and handheld bar code scanners and imager’s for 1D and 2D codes along with the software to make it work. Hundreds of installed systems over twenty years assures our customers of HTE’s ability to provide reliable “best fit” products. Our marking and vision lab tests and approves the product selection for each application. 2D direct marked codes and bar code quality verification are two of our specialties.

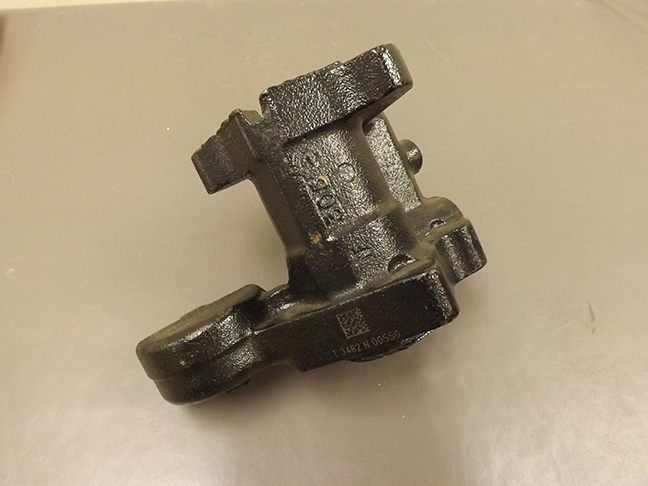

Example of laser marked DPM (Direct Marked Part ) steering gear box

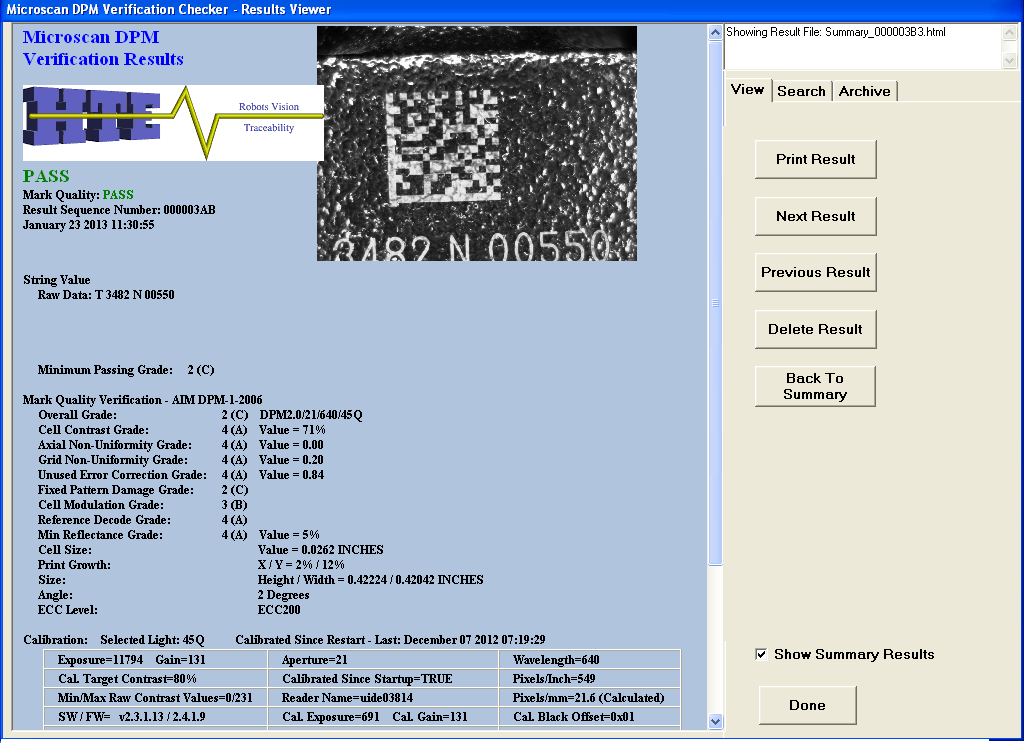

Report from quality grading of laser marked DPM (Direct Marked Part ) Steering gear box.

Quality grading of laser marked steering gear box DPM (Direct Marked Part)