Laser marking : Machine vision : Bar Code : Plantwatch : Track Pac

How AI and Machine Vision Are Reshaping Quality Control: A Complete Guide to Modern Industrial Automation

The manufacturing landscape is experiencing a revolutionary transformation as artificial intelligence (AI) and machine vision technologies converge to redefine quality control processes. This technological evolution is not just changing how manufacturers inspect products—it’s fundamentally reshaping the entire approach to quality assurance in industrial automation.

Understanding AI in Quality Control Systems

How AI is Used in Quality Control

Artificial intelligence in quality control represents a paradigm shift from reactive to predictive quality management. AI systems analyze vast amounts of production data, identifying patterns and anomalies that human inspectors might miss. These intelligent systems continuously learn from production processes, becoming more accurate and efficient over time.

AI applications in quality control include:

- Pattern Recognition: Identifying subtle defects through advanced algorithms

- Predictive Analytics: Forecasting potential quality issues before they occur

- Real-time Decision Making: Instantly determining pass/fail criteria

- Process Optimization: Continuously improving inspection parameters

- Data Integration: Connecting quality data across multiple traceability solutions

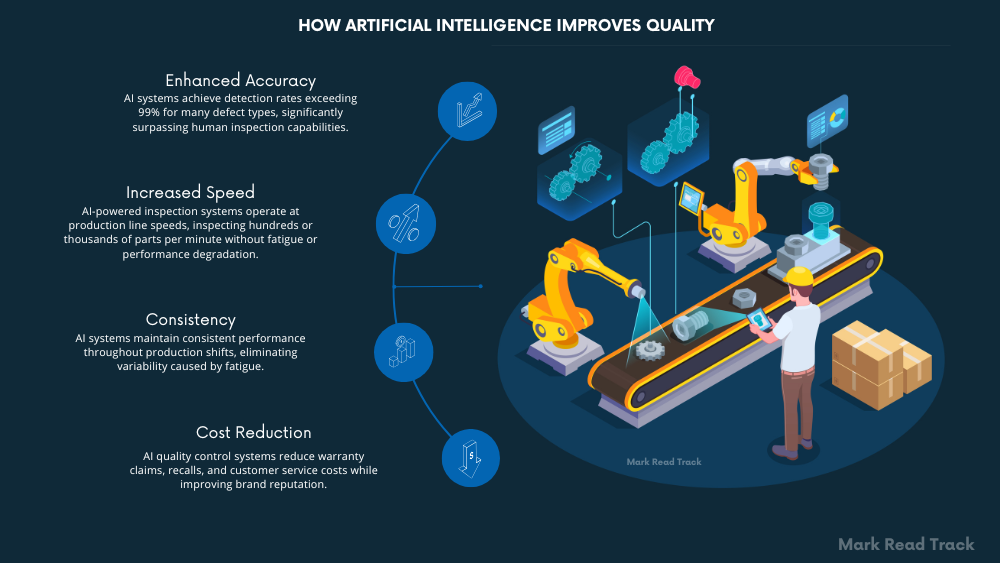

How Artificial Intelligence Improves Quality

The integration of AI into quality control systems delivers measurable improvements across multiple dimensions:

- Enhanced Accuracy: AI systems achieve detection rates exceeding 99% for many defect types, significantly surpassing human inspection capabilities. Machine learning algorithms can identify microscopic defects, color variations, and dimensional inconsistencies with precision measured in micrometers.

- Increased Speed: AI-powered inspection systems operate at production line speeds, inspecting hundreds or thousands of parts per minute without fatigue or performance degradation. This capability is particularly crucial in high-volume manufacturing environments.

- Consistency: Unlike human inspectors, AI systems maintain consistent performance throughout production shifts, eliminating variability caused by fatigue, distraction, or subjective interpretation.

- Cost Reduction: By preventing defective products from reaching customers, AI quality control systems reduce warranty claims, recalls, and customer service costs while improving brand reputation.

Machine Vision vs. AI Vision: Understanding the Distinction

What is the Difference Between Machine Vision and AI Vision?

While often used interchangeably, machine vision and AI vision represent different technological approaches to automated inspection:

Traditional Machine Vision:

- Rule-based systems programmed for specific inspection tasks

- Relies on predetermined algorithms and threshold values

- Effective for well-defined, consistent inspection requirements

- Limited adaptability to variations in products or conditions

AI Vision:

- Learning-based systems that adapt and improve over time

- Uses neural networks and deep learning algorithms

- Handles complex, variable inspection scenarios

- Continuously optimizes performance based on new data

Machine Vision Systems for Industrial Quality Control

What are Machine Vision Systems for Industrial Quality Control Inspections?

Hardware Components:

- High-resolution cameras with specialized sensors

- Precision lighting systems for optimal illumination

- Computational platforms for image processing

- Mechanical positioning systems for accurate part presentation

Software Elements:

- Image acquisition and processing algorithms

- Pattern recognition and analysis tools

- Statistical quality control modules

- Integration interfaces for manufacturing execution systems (MES)

The Four Basic Types of Machine Vision Systems

Understanding the fundamental categories of machine vision systems helps manufacturers select appropriate solutions for their specific quality control requirements:

1. 2D Vision Systems

- Analyze flat, two-dimensional images

- Ideal for surface inspection, label verification, and dimensional measurements

- Common applications include PCB inspection and packaging verification

3. Thermal Vision Systems

- Detect temperature variations and heat signatures

- Critical for identifying defects in electronic components and welds

- Particularly valuable in continuous process monitoring

2. 3D Vision Systems

- Capture depth information and dimensional data

- Essential for volume measurements and complex geometry inspection

- Used in automotive part verification and medical device manufacturing

4. Hyperspectral Vision Systems

- Analyze materials across multiple wavelengths

- Identify chemical composition and material properties

- Essential for pharmaceutical and food industry applications

Visual Inspection in Quality Control

What is Visual Inspection in Quality Control?

Visual inspection represents the cornerstone of quality control processes, encompassing both human and automated methods for detecting defects, verifying compliance, and ensuring product integrity. Modern visual inspection combines traditional techniques with advanced AI-powered systems to achieve comprehensive quality assurance.

- Manual Inspection: Human-based visual assessment

- Semi-Automated Inspection: Human-guided machine systems

- Fully Automated Inspection: AI-powered autonomous systems

- Intelligent Inspection: Self-learning adaptive systems

What are Vision Systems Primarily Used in Industry For?

- Industrial vision systems serve multiple critical functions across manufacturing operations:

- Defect Detection: Identifying surface flaws, cracks, scratches, and other visual defects that could affect product performance or appearance.

- Dimensional Verification: Measuring critical dimensions, tolerances, and geometric features to ensure compliance with engineering specifications.

- Assembly Verification: Confirming correct component placement, orientation, and completeness in assembled products.

- Character Recognition: Reading and verifying text, codes, and markings for traceability and quality documentation through advanced reading systems.

- Color and Appearance Analysis: Evaluating color consistency, surface finish, and aesthetic properties according to quality standards.

Comprehensive Quality Control Systems

What are the Different Types of Quality Control Systems?

Statistical Process Control (SPC):

- Uses statistical methods to monitor production processes

- Identifies trends and variations before defects occur

- Integrates seamlessly with AI-powered inspection systems

Six Sigma Quality Control:

- Data-driven methodology for eliminating defects

- Uses advanced statistical analysis and AI pattern recognition

- Achieves near-perfect quality levels (3.4 defects per million opportunities)

Total Quality Management (TQM):

- Capture depth information and dimensional data

- Comprehensive approach involving all organizational levels

- Emphasizes continuous improvement and customer satisfaction

- Leverages AI analytics for organization-wide quality insights

Lean Quality Control:

- Focuses on waste elimination and process efficiency

- Integrates AI optimization for streamlined inspection processes

- Emphasizes continuous flow and just-in-time quality verification

How Do Vision Inspection Systems Work?

- Image Acquisition: The process begins with high-resolution cameras capturing detailed images of products under precisely controlled lighting conditions. Advanced MRT vision systems use multiple cameras and specialized illumination techniques to reveal even the most subtle defects.

- Image Processing: Powerful algorithms analyze captured images, applying filters, enhancement techniques, and geometric corrections to prepare data for analysis. This stage often involves real-time processing capabilities to maintain production speeds.

- Feature Extraction: AI algorithms identify and measure specific features, dimensions, and characteristics relevant to quality requirements. Machine learning models trained on thousands of examples can recognize complex patterns and anomalies.

- Decision Making: Based on predefined criteria and learned patterns, the system makes pass/fail decisions, triggers alarms, or initiates corrective actions. Advanced systems provide detailed reporting and traceability data for continuous improvement.

The Four Types of Quality Inspection

Understanding Quality Inspection Categories

1. Incoming Inspection

- Evaluates raw materials and components before production

- Prevents defective inputs from entering manufacturing processes

- Uses AI-powered barcode verification systems for rapid supplier quality verification

3. Final Inspection

- Comprehensive evaluation of finished products

- Ensures compliance with all quality specifications

- Often combines multiple inspection technologies and marking verification systems

2. In-Process Inspection

- Monitors quality during manufacturing operations

- Enables real-time corrections and process adjustments

- Integrates with production systems for immediate feedback

4. Outgoing Inspection

- Final verification before shipment to customers

- Focuses on packaging, labelling, and shipping requirements

- Maintains traceability and quality documentation

The Four Points of Inspection

1. Conformance to Specifications

- Dimensional accuracy and tolerance verification

- Material properties and performance characteristics

- Functional testing and operational validation

3. Process Compliance

- Manufacturing procedure adherence

- Environmental condition monitoring

- Equipment performance verification

2. Defect Detection and Classification

- Surface quality and appearance standards

- Structural integrity and safety requirements

- Hidden defects through advanced sensing technologies

4. Documentation and Traceability

- Quality record maintenance

- Regulatory compliance verification

- Customer requirement fulfillment through comprehensive traceability systems

Advanced Quality Control Methodologies

The Four Aspects of Quality

1. Performance Quality

- Functional capabilities and reliability

- Efficiency and effectiveness metrics

- Customer satisfaction and usability

3. Durability Quality

- Product lifespan and reliability

- Resistance to wear and degradation

- Long-term performance maintenance

2. Conformance Quality

- Adherence to specifications and standards

- Consistency and repeatability

- Regulatory compliance and certification

4. Aesthetic Quality

- Visual appearance and finish

- Brand consistency and market appeal

- Customer perception and satisfaction

The Four Methods Used in Quality Control Production

1. Prevention-Based Quality Control

- A proactive approach to preventing defects before occurrence

- Design for manufacturability and quality

- Process capability analysis and optimization

3. Correction-Based Quality Control

- Addresses identified quality issues through corrective actions

- Root cause analysis and process improvement

- Continuous monitoring and adjustment

2. Detection-Based Quality Control

- Reactive approach, identifying defects after occurrence

- Traditional inspection and testing methods

- AI-enhanced detection capabilities

4. Management-Based Quality Control

- Systematic approach to quality planning and control

- Integration of quality systems across organizations

- Strategic quality management and improvement

The Future of AI in Quality Control

Emerging Technologies and Trends

The future of AI in quality control promises even more revolutionary advances:

- Deep Learning Evolution: Next-generation neural networks will handle increasingly complex inspection tasks, recognizing subtle patterns and anomalies beyond current capabilities.

- Edge Computing Integration: AI processing will move closer to production lines, enabling real-time decision-making with minimal latency and enhanced data security through high-speed testing systems.

- Augmented Reality Quality Control: AR systems will overlay AI-generated quality information onto real-world views, assisting human inspectors and providing interactive quality guidance.

- Predictive Quality Analytics: Advanced AI will predict quality issues days or weeks before they occur, enabling proactive maintenance and process adjustments.

- Autonomous Quality Systems: Fully autonomous quality control systems will operate independently, making complex decisions and adjustments without human intervention.

Integration with Industry 4.0

- IoT Connectivity: Quality systems will connect seamlessly with sensors, machines, and enterprise systems, creating comprehensive quality ecosystems through industrial automation solutions.

- Digital Twin Technology: Virtual representations of production processes will enable quality simulation and optimization before implementation.

- Blockchain Traceability: Immutable quality records will provide complete product history and supply chain transparency.

- Collaborative Robotics: Quality control robots will work alongside human operators, combining AI precision with human judgment.

Implementation Strategies for AI Quality Control

Planning and Deployment Considerations

Assessment and Planning:

- Evaluate current quality control processes and limitations

- Identify opportunities for AI enhancement and automation

- Develop an implementation roadmap with clear milestones

Training and Development:

- Prepare the workforce for AI technology integration

- Develop new skills and competencies

- Establish maintenance and support procedures for vision and marking systems

Technology Selection:

- Choose appropriate AI algorithms and machine learning models

- Select compatible hardware and software platforms, including Omron vision systems

- Ensure scalability and future expansion capabilities

Continuous Improvement:

- Monitor system performance and effectiveness

- Collect feedback and optimization opportunities

- Implement updates and enhancements regularly